With a forward-thinking mindset, the Israeli EIC-funded company Brevel develops, as its core business, an innovative technology for the production of microalgae-based ingredients. Their solution keeps collecting good reactions from the market with a newly won seed funding round in the value of $8.4 million.

Brevel gathered this amount from a group of investors that included FoodHack, Good Startup VC, Tet Ventures and Nevateam Ventures, among other within the food tech industry. Israel’s Innovation Authority also took part in the round, contributing in the form of non-dilutive grants.

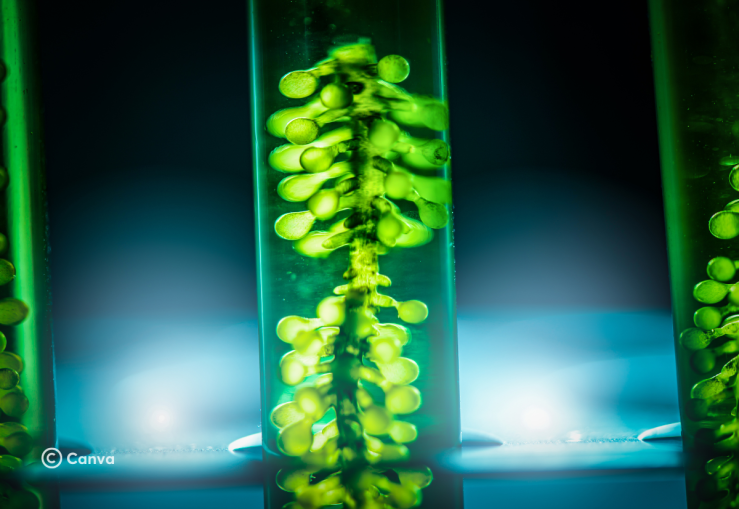

Aspiring to contribute to a more sustainable world, Brevel sees in microalgae a crucial element in this green picture of the future, with microalgae-based ingredients becoming a natural part of life and a first-of-its-kind viable solution for a wide range of industries. Thus, Brevel is developing a disruptive microalgae cultivation technology which dramatically reduces the cultivation costs for light-dependent microalgae and enables penetration into new markets where microalgae biomass and derived products are looked for.

Brevel’s technology is based on shifting from a very large, relatively inefficient and labour-intensive outdoor cultivation system to completely closed, sterile and fully automated indoor photobioreactors. Their patented product provides a cost reduction of as much as 90%, allowing significantly higher yields from land compared to current outdoor state-of-the-art photobioreactors.

We had the chance of hearing from Yonatan Golan, CEO of Brevel, who told us about their next steps after receiving the recent funding: “The investment enables us to accelerate our entrance into the market with a unique alternative protein solution which is not only very sustainable and flavour neutral, but is also at cost parity with the currently widely used protein sources - soy and pea. Having such a solution at an affordable cost is a major breakthrough in the food industry and puts us on the path of being the #1 choice of plant-based protein. Additionally, with this financing we are now building our first commercial pilot facility which will be up and running in the next few months and will provide alternative protein to our first customers and partners.”. Yonatan added that the company is working to “Further our product and process to provide the maximal value to our partners. Also, we are now working towards forming agreements to large scale manufacturing facilities as joint ventures with global partners.”.

Just last week, Brevel signed a Memorandum of Understanding (MoU) with the community of Kibbutz Yotvata (southern Israel), agreeing to build a commercial-scale manufacturing facility for the cultivation and production of microalgae-based protein and related products for the food and beverage industry. The facility will be home to the largest fermentation reactors of their kind, sized at 30,000L, which will have the capacity to produce 900,000L per year when fully operational, in order to support the rising demand in the EU and Middle Eastern markets.

Brevel received a Phase 2 grant and blended finance from the European Innovation Council to develop a cutting-edge technology that can significantly reducing cultivation costs for light-dependent microalgae.