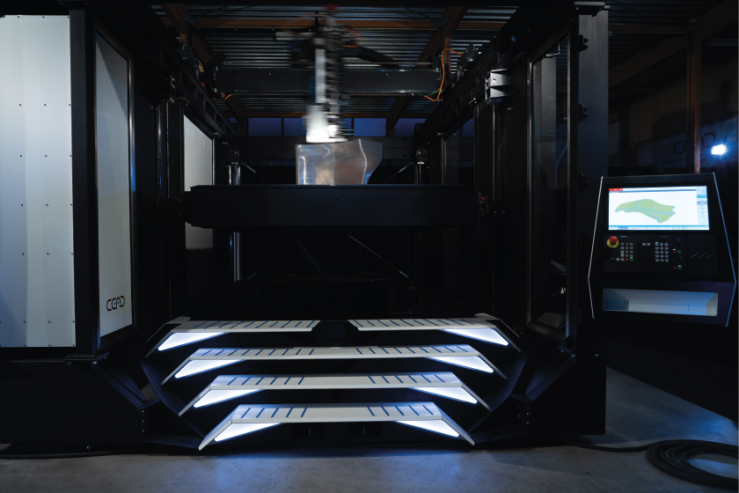

European Innovation Council pilot's funded company CEAD was the winner in the area of Innovative Processes with its development of an additive manufacturing process, which permits the use of continuous fibres in large components required for industrial applications.

Until 2017, additive manufacturing with continuous fibres was impossible, for example, for the production of cladding elements, exterior panels for trains or autoclave moulds. The development of CFAM technology is now said to enable continuous fibres to be used in high-speed, 3D printing of large format components. It can be used to manufacture parts with dimensions of up to 4 m x 2 m x 2 m x 1.5 m. Production plants can print these products with an average output of 15 kg/h and a maximum output of 25 kg/h. The process for combining continuous fibres and thermoplastic materials on this scale has already been patented. It uses a single-screw extruder which functions with both glass and carbon fibres as well as practically all thermoplastic materials, from PP to PEEK.

The AVK has presented its prestigious Innovation Awards in three categories at the award ceremony that took place during the trade fair Composites Europe in Stuttgart. The awards recognise new and pioneering innovations and place a particular emphasis on sustainability. The jury, comprising experts in the composites industry, were impressed by the high quality of the submissions and selected the winners in three categories: Products and Applications, Processes, and Research and Science.

“It's always exciting to discover the ways in which companies and universities are working make composites even better. There is still enormous potential for the development of these economically and ecologically significant materials,” said Elmar Witten.

CEAD is a technology supplier of 3D printing equipment on the frontier of large scale composite additive manufacturing. In 2017 the Netherlands company started the development of their world wide unique and patented Continuous Fibre Additive Manufacturing (CFAM) technology, which makes it possible to 3D print large scale continuous fibre reinforced products with high speed.

The company received a Phase 2 grant from the EIC SME Instrument program in 2017 of 963.813 €.

View CEAD's information on the EIC SME Instrument data hub.

DISCLAIMER: This information is provided in the interest of knowledge sharing and should not be interpreted as the official view of the European Commission, or any other organisation.